Categories

New products

-

Lens Ring Joint Gasket

With professional Lens Ring Joint Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Lens Ring Joint Gasket manufacturers and suppliers.

-

Double Jacket Gasket

With professional Double Jacket Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Double Jacket Gasket manufacturers and suppliers.

-

Corrugated Gaskets

With professional Corrugated Gaskets factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Corrugated Gaskets manufacturers and suppliers.

-

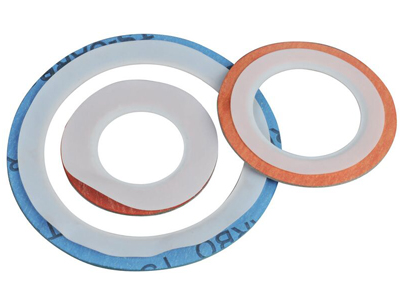

PTFE Envelope Gasket

With professional PTFE Envelope Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China PTFE Envelope Gasket manufacturers and suppliers.

-

Rubber Sheet

With professional Rubber Sheet factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Rubber Sheet manufacturers and suppliers.

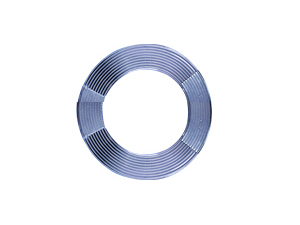

Modified Ptfe Gasket Tape

Modified PTFE gasket are in order to meet the needs of customers to different working conditions, and reduce the cost. Kaxite research and design the modified PTFE gaskets.

Modified PTFE gaskets improved performance over conventional PTFE, Reduced product loss and emissions. Excellent bolt torque retention, unique manufacturing process minimizes cold flow problems typical of skived and expanded PTFE Sheets. Withstands a wide range of chemicals for extended service life in a wide variety of applications.

Features of Modified PTFE Gasket Materials| Excellent chemical resistance |

|---|

| Improved performance over conventional PTFE |

| Resistance to cold flow / creep |

|

Temperature stable from -268 |

| Suitable for high temperature - pressure applications |

| Improved seal & excellent bolt torque retention |

| Outstanding dimensional stability under thermal stress |

| Reduced product loss and emissions |

| Approved for pharmaceutical and food processing use |

| TUV certified in accordance with TA-Luft requirements |

| Resistance to wear and abrasion |

| Supplied as precision cut gaskets to any shape & size and quantity or in sheet form to max size 1500mm x 1500mm |

| Available in a range of 5 thicknesses 0.8mm/1.0mm/1.6mm/2.0mm and 3.2mm |

Benefits:

> Reduced creep relaxation;

> Chemical resistant;

> Cost saving;

> Tighter seal.

Supplied Sizes:

60'' x 60'' , 70'' x 70'', etc.

Thickness: 1/16'', 1/8'', etc.

Specification:

| SUNWELL Code | MF4350 | MF4354 | MF4351 | MF4353 |

| Color | Fawn | Blue | Off-white | Black |

| Photos |

|

|

|

|

| Composition | PTFE with silica | PTFE with glass microspheres | PTFE with barium sulfate | PTFE with graphite |

|

Temperature Minimum Cont. max. |

-268 oC +260 oC |

-268 oC +260 oC |

-268 oC +260 oC |

-268 oC +260 oC |

| Pressure bar | 75 | 55 | 55 | 75 |

| Sealability cm3/s (GB/T9129-2003) | < 1 x 10-3 | < 1 x 10-3 | < 1 x 10-3 | < 1 x 10-3 |

| Creep Relaxation % ASTM F38 | 20 | 35 | 18 | 35 |

| Compressibility Range % ASTM F36-99 | 10~15 | 25~40 | 5~12 | 7~19 |

| Recovery % ASTM F36-99 | > 21 | >25 | >35 | >35 |

| Tensile Strength N/mm2 ASTMF 152-95 | 13 | 12 | 11 | 11 |

| Flammability | Will not support flame | |||

| Bacterial Growth | Will not support | |||