Categories

New products

-

Lens Ring Joint Gasket

With professional Lens Ring Joint Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Lens Ring Joint Gasket manufacturers and suppliers.

-

Double Jacket Gasket

With professional Double Jacket Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Double Jacket Gasket manufacturers and suppliers.

-

Corrugated Gaskets

With professional Corrugated Gaskets factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Corrugated Gaskets manufacturers and suppliers.

-

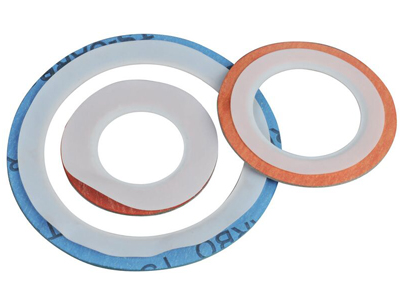

PTFE Envelope Gasket

With professional PTFE Envelope Gasket factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China PTFE Envelope Gasket manufacturers and suppliers.

-

Rubber Sheet

With professional Rubber Sheet factory, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the leading China Rubber Sheet manufacturers and suppliers.

Graphite Sheet Reinforced with Metal Foil

Kaxite Graphite sheet reinforced with metal foil is made from there layers, at the middle of the flexible graphite sheet is one stainless steel foil. Through specially pressing or sticking process. The insert materials can be SS304, SS316, Nickel, etc. It can be used in the condition of high temperature, high pressure and sealing. .

Description

Flexible Graphite Sheet, normally we call it "Expanded Graphite Sheet", it is made from high quality and purity flake graphite, which is gone through chemical treatment, expanding under high temperature and then rolling. It is a basic material for making different kinds of graphite sealing products.

Kaxite B201N - Unclear grade Flexible graphite sheet

Typical Application

> Suitable for making gaskets of cylinders for are compressors, internal combustion engines and packing for different kinds of piping, and flanges

> The condition of high pressure and high temperature

Prime Features

> Lone life and less maintenance

> Replacement for asbestos, new more applications are being indentified daily.

> Excellent comprehensive properties

> Good compressibility and resilience, small stress relaxation, fine compensation function

Technical Data

| Item | Industrial grade | Unclear grade |

| Tolerance of density g/cm3 | +/-0.06 | +/-0.05 |

|

Carbon content |

98/99 | 99.5 |

|

Tensile strength |

3~20 | 5~25 |

|

Compressibility |

30 | 30 |

|

Recovery |

15 | 15 |

| Sulphur content | 1200 | 700 |

| Chlorine content | 50 | 25 |

| Stress relaxation rate % | 10 | 10 |

| Lgnition loss | 2.0 | 0.5 |

Temperature: -240~+500oC under oxidizing environment

-240~+3500oC under non-oxidizing environment

PH: 0~14

Dimensions

| Item | Sheets |

| Density g/cm3 | 1.0 |

| Length | 500, 1000,1500mm |

| Width mm | 1000,1500, 2000 |

| Thickness mm | 0.5~3.0 |